Latest News & Events

World Micro Announces the Purchase of X-Ray and Decapsulation Equipment

Over $250,000 Invested in Counterfeit Detection

Atlanta, GA, November 24, 2009 – Georgia-based electronics distributor, World Micro, today announced that it has made additional investments to further protect its customers from the onslaught of counterfeit and sub-standard parts that are infiltrating every link in the global electronic component supply chain.

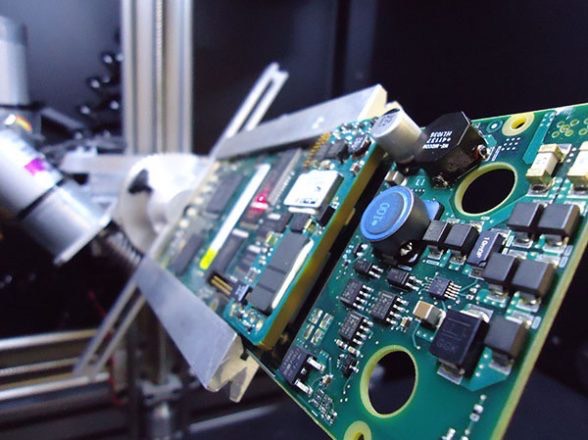

In addition to existing quality investments, World Micro announces the purchase of a self contained X-Ray machine and a Decapsulation Machine. Together, these machines will allow an inside view of the component to verify authenticity.

World Micro’s President Dan Ellsworth states, “Our mission is to become the best company in the world at detecting counterfeit components and these investments show that we are serious about achieving this objective.”

Steve Zweig of Glenbrook Technologies, Inc. commented, “Our award winning X-Ray camera technology results in unmatched detail. The versatility of the machine allows quick inspection of every component on a reel, without removing the components from the carrier tape. We are excited World Micro has selected our system for implementation”

The machine’s capability of rotating the component a full 360 degrees will also provide the ability to protect against components that have been mishandled and subjected to either electrostatic discharge or internal moisture buildup. It is a non-destructive test process that will not harm the component.

In addition, World Micro has purchased a decapsulation station manufactured by Nisene Technology Group that will allow the removal of the plastic top of a component. It will allow magnified (500x) inspection of the interior of the circuit, as well as confirming the die part number matches the component’s part number.

Although this is a destructive process, it provides invaluable detail of the tested component.

“It is an honor to know that World Micro has selected our decapsulation equipment and that we are playing a vital role in stopping the growing problem of counterfeit components.” said Erik Jordan of Nisene Technology Group.

Art Ogg, World Micro’s Director of Quality and Industry leader in counterfeit detection and avoidance training, agreed, “With the purchase of this equipment, we are demonstrating relentless commitment to protect our customers. There are few companies that have reached the level of counterfeit detection that is found at World Micro.”

World Micro has become a leader in quality with ISO 9000, AS9120 and ANSI/ESD $20.20 certification, IDEA membership and certified professional quality engineers using a 72 point inspection procedure on all incoming parts. All of World Micro’s suppliers are qualified through a rigorous audit process. World Micro has pushed the quality commitment up and down the supply chain.

ABOUT – World Micro is a global electronics distribution company. Since, 1995, World Micro has helped Purchasing and Engineering Departments at leading OEM, EMS, and ODM companies research, design, source, stock, procure, inventory, and manage board level components, embedded computing products and military/aerospace specialty hardware. World Micro is headquartered in Roswell, Georgia.

Contact:

Todd Ballew

World Micro, Inc

800-400-5026

tballew@worldmicro.com

www.worldmicro.com