JewelBox Series

Real-time X-ray Inspection Systems

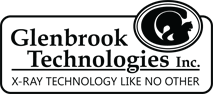

JewelBox x-ray inspection systems feature ultra-high resolution, powerful microfocus x-ray tubes, five-axis, and positioners. The JewelBox Series is divided into three broad categories: JewelBox 70-T, JewelBox 90-T, 100-T, 110-T, and Ultra Compact each of which can be customized for specific applications.

JewelBox-70T™

The JewelBox-70T delivers superior image quality with excellent resolution and sensitivity for laboratory and failure analysis applications. The system’s 10-micron MicroTech™ x-ray source provides magnification from 7X to 2000X, with resolution of 100 line pairs/mm.

Description

JewelBox-70T, Real-time, High Resolution X-ray Inspection System with Crystal-X Imaging for up to 2000x Magnification

The JewelBox-70T delivers superior image quality with excellent resolution and sensitivity for laboratory and failure analysis applications. The system’s patented XRTV X-ray camera and Crystal-X imaging plus a 10-micron MicroTech™ x-ray source provide magnification from 7X to 2000X, with resolution of 100 line pairs/mm.

The ability to manipulate the subject with the five-axis positioner and simultaneously view it from any angle allows the operator to produce accurate images quickly during failure analysis.

All JewelBox inspection systems come with the pre-installed GTI-5000 Image Processing Workstation. The extensive features of the GTI-5000, including Auto-BGA and void measurement, make the JewelBox-70T an ideal laboratory instrument to inspect electronic components and more. For customers who don’t need the advanced capabilities of the GTI-5000, the economical GTI-1000 is available as an option.

Specifications

Specifications:

- Operating voltage: 120v/220v/50-60 hz

- Anode voltage: 80 kV (adjustable)

- Anode current: 100 microamps (adjustable)

- Magnification: variable from 7X to 2000X

- Focal spot size: 10 micron

- Focal spot to image plane distance: 13 7/16″ (341.3mm) (factory preset)

- Nominal exterior dimensions: 35 1/8″W x 43 1/8″D x 64 1/4″H (892.175mm L x 1095.375mm W x 1631.95mm H)

- Inspection compartment dimensions: 28 1/2″W x 30″ D x 23 3/4″H (723.9mm L x 1095.375mm W x 1631.95mm H)

- Manipulator: five-axis joystick positioner

- Image Processing: GTI-5000 image processing workstation pre-loaded on PC computer with monitor, keyboard and mouse

- Computer console

Options:

- Image Processors

- Laptop

- Programmable Motion Control

- Dual Camera

Applications:

- Multilayer and assembled pc boards including BGA, QFN, LED, and other device

- Counterfeit Component Detection

- Failure Analysis

- Connectors, Cables, and Sensors

- IC Packaging and Wire Bonds

- Battery Inspection

- Medical Electronics including hearing aids and pacemakers

Video

JewelBox-90T/100T/110T™

All JewelBoxes deliver precision x-ray images of ultra-high resolution and grey scale accuracy without the aberrations of voltage blooming and image distortion prevalent in other systems.

Both the JewelBox-100T and 110T contain all the features of the JewelBox-90T. The JewelBox-110T contains a higher voltage of 110kV 5-micron focal spot x-ray source. The JewelBox-100T contains a higher voltage of 100kV 5-micron focal spot x-ray source.

Description

Real-time X-ray Inspection System

The JewelBox-90T delivers precision x-ray images of ultra-high resolution and grey scale accuracy without the aberrations of voltage blooming and pincushioning prevalent in other systems.

Glenbrook’s patented, award-winning X-ray camera technology includes:

- Magnification from 7X to 2000X

- Port openings for longer devices

- 5-micron MicroTech™ x-ray source

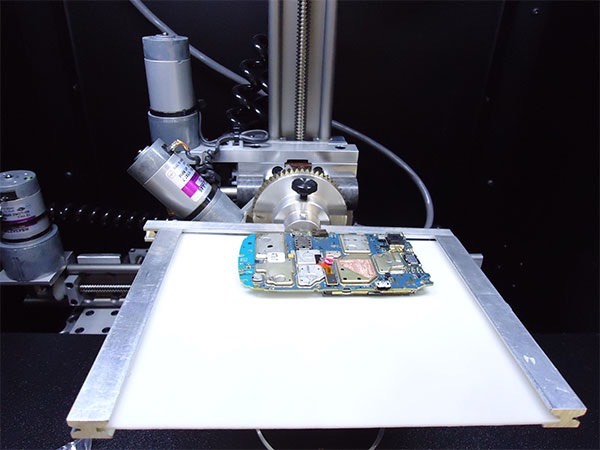

- 360 degree rotation and 45 degree tilt

- 5 axis manipulator

- Resolution of 100 line pairs/mm

The JewelBox-90T uses a powerful 90kV micro-focus x-ray tube for deep penetration of dense materials, including metal BGAs. The camera’s sensitivity allows imaging of low-density materials such as plastics, polymers, collagen and urethanes, as well as very small parts fabricated from ceramics and titanium.

All JewelBox inspection systems come with a pre-installed GTI-50 Image Processing Workstation. The GTI-50 includes an Auto-BGA and void measurement for inspection of electronic components.

Specifications

JewelBox 90T:

- Anode voltage: 90 kV, 5-7 micron focal spot x-ray tube

JewelBox 100T:

- Anode voltage: 100 kV, 5 micron focal spot x-ray tube

JewelBox 110T:

- Anode voltage: 110 kV, 5-7 micron focal spot x-ray tube

Specifications for JewelBox 90T/100T/110T:

- Operating voltage: 120v/220v/50-60 hz (self-switching)

- Focal spot to image plane distance: 9-12″ (228.6mm – 304.8mm) (factory preset)

- Outside dimensions: 35 1/8″W x 43 1/8″D x 74″H (892.175mm L x 1095.375mm W x 1879.6mm H)

- Inspection compartment dimensions: 30″W x 31″D x 26″H (762mm W x 787.4mm L x 660.4mm H) (customizable up to 36″ x 36″ (914.4mm x 914.4mm) on request)

- Manipulator: five-axis joystick positioner

- Image Processing: GTI-50 and USB frame grabber

Options:

- Image Processors

- Laptop

- Programmable Motion Control

- Dual Camera

Applications:

- Multilayer and assembled pc boards including BGA, QFN, LED and other device

- Failure Analysis

- Component Authenticity Inspection

- Connectors, Cables and Sensors

- IC Packaging and Wire Bonds

- Battery Inspection

- Medical Electronics including hearing aids and pacemakers

Video

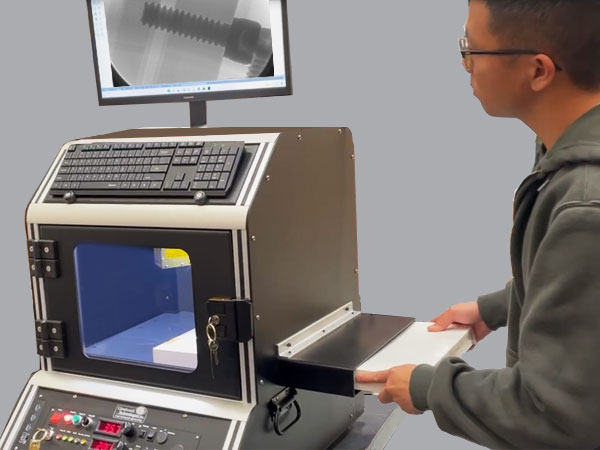

Ultra-Compact™

Glenbrook Technologies redefines X-ray Inspection with our smallest JewelBox Micro focus x-ray system yet. With dimensions of just 22”W x 26”L, it’s small enough to fit on a standard desk, in an office or small lab. But it’s big in capabilities with >500x magnification , 5 axis manipulator and advanced image processing.

Description

Real-time X-ray Inspection System

Our smallest Jewelbox micro focus x-ray system with dimensions of just 22”W x 26”L, small enough to fit on a standard desk, or small lab. Ideal for laboratory and failure analysis applications.

Glenbrook’s unique x-ray camera technology captures x-ray images with relatively low kV x-ray emission. The ability to manipulate the subject with the five-axis positioner and simultaneously view it from any angle allows the operator to produce accurate images quickly during failure analysis.

This unit has the ability to have an internal computer and flip up monitor with wireless mouse and keyboard. This all in one feature makes it great for desktop applications in which space is a concern without sacrificing performance. Wifi, bluetooth and dual display enable.

All Jewel Box inspection systems include one of the GTI Series of Image Processing Software Packages. We can suggest which software packages best fits your application.

Specifications

The JewelBox Ultra Compact includes:

- Magnification from 7X to 2000X

- Port openings for longer devices

- 10-micron MicroTech™ x-ray source

- 360 degree rotation and 45 degree tilt

- 5 axis manipulator

- Resolution of 100 line pairs/mm

Specifications: (Click Here For Download)

- Operating voltage: 120V/60hz or 220V/50hz

- Anode Voltage: 0 to 80 kV (Adjustable)

- Anode Current: Up to 200 micro-amps (Adjustable)

- Field of View: 25 millimeters

- Resolution: 10 microns (depending on magnification)

- Magnification: 7 to 500 X (variable)

- Focal sopt size: 10 micron

- Nominal Exterior Dimensions: 22”W x 26”D x 27¼”H

- Manipulator: five-axis joystick positioner

- X/Y Object Travel Distance: 5” x 9″

- Laser Locator for precise location

- Image Processor: GTI-2000 Image Processor with variable frame averaging, contrast adjustment, measurement capability, image save in tiff, jpg or avi video formats.

- CE Approved

Applications:

- Multilayer and assembled pc boards including BGA, QFN, LED and other device

- Component Authenticity Inspection

- Connectors, Cables and Sensors

- IC Packaging and Wire Bonds

- Battery Inspection

- Medical Electronics including hearing aids and pacemakers

Video

Our Latest Innovations

Our latest innovations, Programmable Motion Control and Dual Camera capabilities are now available for the JewelBox 70T, JewelBox 90T and JewelBox 110T X-ray Inspection Systems.

Programmable Motion Control

Programmable motion control is now available for the JewelBox 70T and JewelBox 90T X-ray Inspection Systems, and can also be included in any new system or retrofit into existing systems. Using the simple graphical user interface, the operator can easily create repeatable programs for automated inspection applications with precision within +/-0.005″.

Programmable Motion Control Brochure

Programmable Motion Control Press Release

Dual X-ray Camera

The New Dual Camera combines a 25 mm and 75 mm or 25 mm and 100 mm diameter field of view x-ray camera into the camera body. The larger field of view camera (75 or 100mm diameter) allows you to view more of the device in one image. The smaller field of view camera (25 mm diameter) allows you to see details as a small crack n 1 mil. wire at higher geometric magnification. The Dual Camera feature is available on JewelBox 70T, JewelBox 90T and JewelBox 100T x-ray cameras.

Reel-to-Reel Options

Designed for automated inspection of reels of components to check for component authenticity. Includes GTI-4000 software to compare lead frames, die size and wire bonds of each part to your known good part. The software will identify any part outside the tolerance and save an image of each part.

Watch the latest client video from Radwell International and how they use Glenbrook’s The JewelBox-70T for x-ray inspection of BGAs, counterfeit chips, and more.

See complete line of JewelBox X-Ray Systems

JewelBox X-Ray Images

High-Resolution Inspection for Electronics Fabrication Applications

Progressive magnification allows inspection of multiple details: