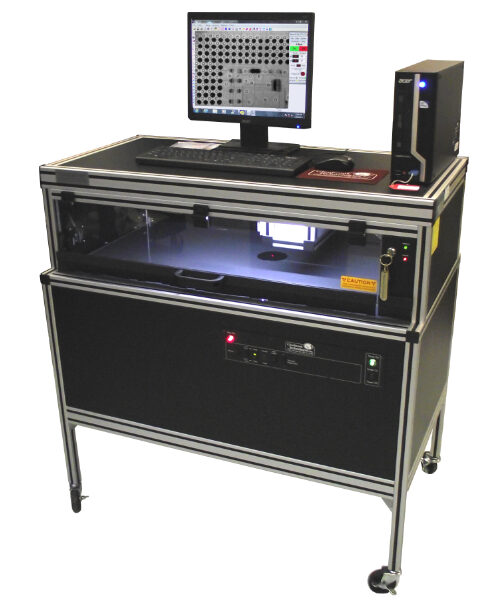

The RTX Series

For X-ray inspection of PCB Boards and More

Glenbrook’s RTX Series of modular, real-time systems include models designed to meet a variety of production requirements including circuit board components. Numerous options make it easy to customize any RTX model to your specific application. All hardware and software elements are fully compatible to ensure the continued value of your equipment.

RTX-113HV MicroTech for High Resolution of PC Boards

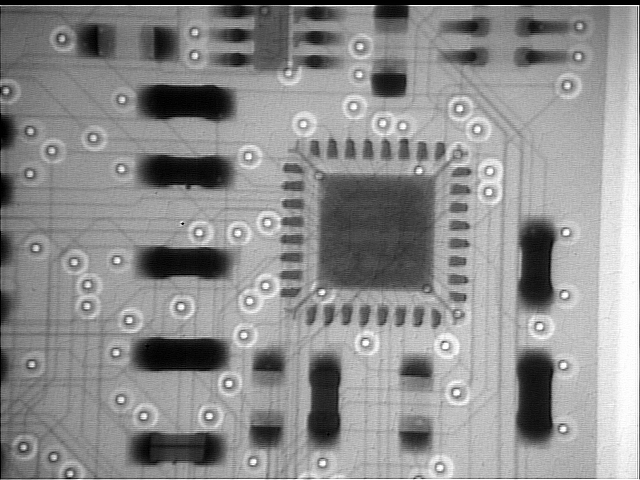

Precision X-ray Inspection for BGAs, QFNs, LEDs, sensors, medical devices, and other packaged devices.

Description

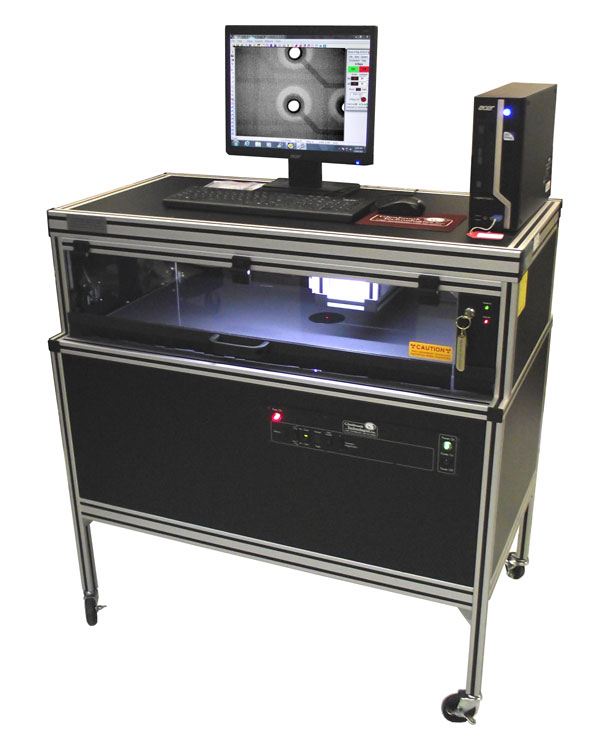

The RTX-113HV MicroTech X-ray System is built to deliver high-resolution inspections of PC boards and various packaged devices in production settings. Boasting a space-saving design and an extremely user-friendly interface, this system is perfectly suited for achieving efficient and accurate quality control.

It utilizes an 80 kV, 5-micron focal spot X-ray tube, providing the resolution necessary to clearly see wire bonds. The system’s cabinet can accommodate PC boards up to 18” x 24” in size. Additionally, the motorized tray offers a versatile scan area of 15” x 15” in the x-y axis, ensuring a thorough X-ray inspection.

Specifications

Dimensions: 60” x 33” x 51”

Operating Voltage: 120v or 220v

Contrast Resolution: Can resolve .001 gold wire

Spatial Resolution: 20 lp/mm (with MicroTech™ option, up to 100 lp/mm)

Anode Voltage: 40Kv-80Kv (PC Controlled)

Anode Current: 20-150 microamps

Magnification: 100x geometric + 225x optical

Motorized X-Y Positioner Travel: 19” x 15”

Cabinet Interior Dimensions:

Motorized X-Y Positioner Travel: 39” x 29” x 14”

Video

RTX-113™

First Tier Machine for Inspecting Multilayer and Assembled Printed Circuit Boards

Description

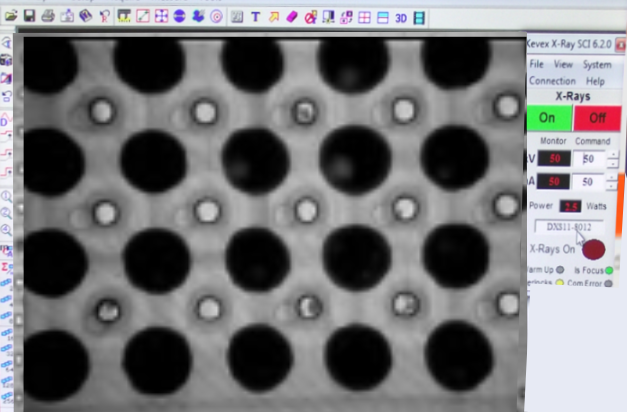

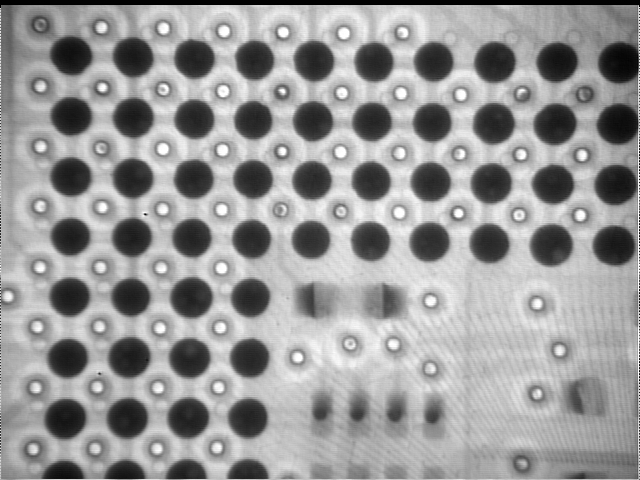

Glenbrook’s RTX-113 is designed for heavy production environments where X-ray is used to inspect PCBs and assembled PCBs containing advanced components such as BGA, micro BGA, QFN and other devices.

The system is very versatile and features Glenbrook’s patented, award-winning X-ray camera technology that generates high-resolution, high-sensitivity images, revealing defects as small as 0.001 inch with a full one inch diameter field of view. The RTX-113 provides affordable real-time X-ray imaging, reliable operation and easy servicing.

Specifications

Dimensions: 44”H x 42”W x 24”D (1066.8mm x 1117.6mm x 609.8mm)

Operating Voltage: 120v, 60hz or 220v, 50hz

Contrast Resolution: Can resolve .001 gold wire

Spatial Resolution: 20 lp/mm (with MicroTech™ option, up to 100 lp/mm)

Anode Voltage: 52 kv or optional 80 kv

Anode Current: 50 or 90 microamps

Magnification: 15x geometric to 50x optical

Focal Spot to Image Plane Distance: 4-6 inches

X-ray Activation Mode: Foot Pedal or PC Controlled

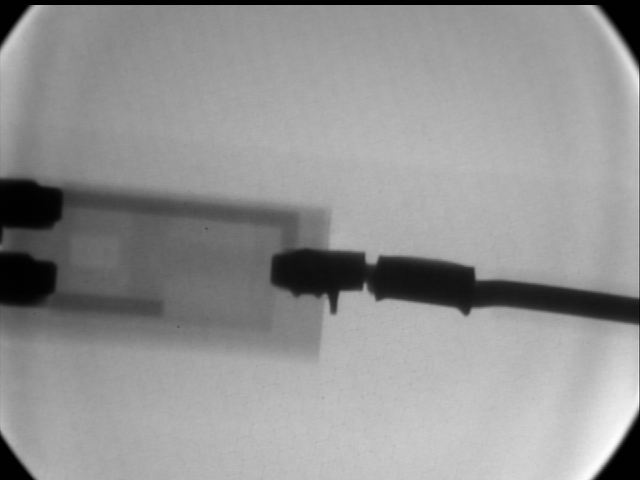

NEW RTX-113 MicroTech for Small Hole Drilling

High Power Magnification System for Small Hole Drilling of Multilayer PCB Boards and Assembled Boards for BGA, LED, QFN and other Devices

Description

The new RTX-113 MicroTech X-ray Inspection System, with enormous capability, is compact enough to fit in a lab or on the production floor. The system employs an 80 kV, 10-micron focal spot tube with our patented XRTV x-ray camera technology now enhanced with Crystal X Imaging for higher contrast. This combination advances our RTX Series for higher resolution and magnification requirements allowing up to 100x geometric and 225x optical magnification

Specifications

Magnification: up to 100x geometric + 225x optical

Dimensions: 44”H x 42”W x 24”D

Operating Voltage: Auto Switching 120v or 220v

Contrast Resolution: Can resolve .001 gold wire

Spatial Resolution: 20lp/mm up to 100lp/mm

Anode Voltage: 0kV‐80kV

Anode Current: 20-150 microamps

RTX-113HV

Designed for inspection of multi-layer and assembled printed circuit boards with dense metal BGAs

Description

Our RTX-113HV system meets all your needs for inspecting BGA packages, including those that contain dense metal heat sinks that require a higher voltage X-ray source to clearly identify and troubleshoot production faults. The cabinet design permits easy integration into even the busiest production environments, and is totally upgradeable. Recommended for lead free inspection requirements

Specifications

- Operating Voltage: 120v/220v, 50-60hz

- Contrast Resolution: Can resolve .001 gold wire

- Spatial Resolution: 20 lp/mm (with MicroTech option,

up to 100 lp/mm) Anode Voltage: 80 kV - Anode Current: 150 microamps

- Machine Dimensions: 50”H x 60”W x 33”D (1270mm x 1524mm x 839mm)

- Focal Spot to Image Plane Distance: 4-6 inches

- XRTV Zoom Camera (4X-50X magnification)

Video

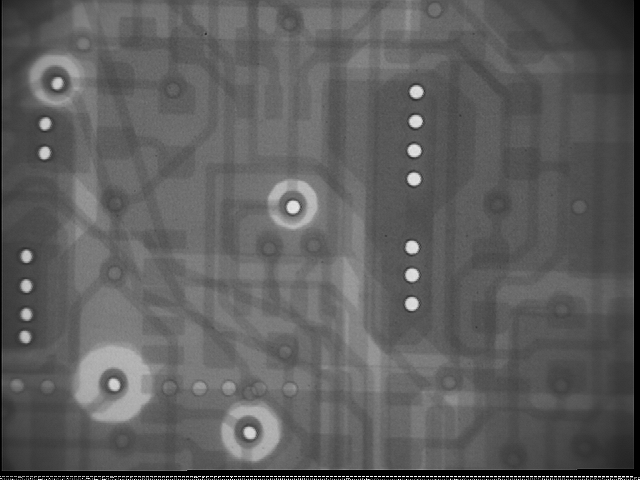

RTX Backplane

Designed for Large and Heavy Backplane Panels for Multilayer and Assembled PC Boards

The RTX Backplane x-ray inspection system can accommodate boards up to 36″ X 42″ weighing up to 40 pounds. It can also inspect up to 32-layer, 0.4 inch thick PCBs and easily detects inner layer errors and checks for hole-pad alignment during drilling. The RTX Backplane can also inspect solder bond integrity of BGAs, LEDs, die attach and Flip Chip locations, and drilled holes on both small and standard boards.

Video